For several decades, TLC Engineering Solutions has been a national leader in the planning, design, and optimization of preconditioned air (PCA) systems, quietly shaping the passenger experience at many of the country’s busiest airports. What began as a forward-thinking engineering effort in the early 1990s has grown into a hallmark of TLC’s aviation practice, backed by data-driven modeling, award-winning performance, and ongoing reinvestment in the next generation of PCA solutions.

This long-running involvement demonstrates not only TLC’s technical depth but also the firm’s enduring relationships with clients and facilities, returning decades later to upgrade the very systems they originally pioneered. TLC’s expertise in preconditioned air systems has shaped large aviation programs across the country for decades, leaving a measurable impact at some of the busiest airports in the United States.

At Seattle Tacoma International Airport, TLC’s centralized PCA system, serving 73 gates, became the first in North America to receive an Airport Council International award for reducing carbon emissions. The system delivers extraordinary operational benefits, saving approximately five million gallons of fuel each year, cutting airline fuel costs by an estimated fifteen million dollars annually, and eliminating roughly 40,000 metric tons of greenhouse gases. Beyond the environmental gains, the design significantly reduces apron noise and enhances overall sustainability on the airfield. With ongoing redesign and repiping work planned for Airside A, the story is still unfolding.

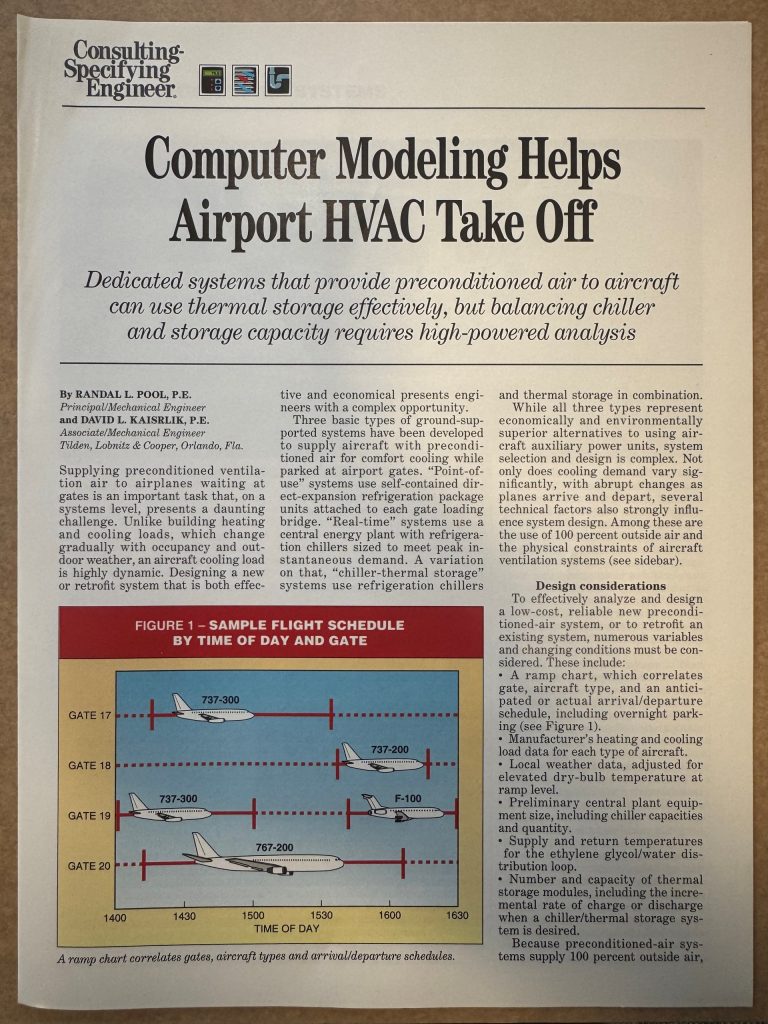

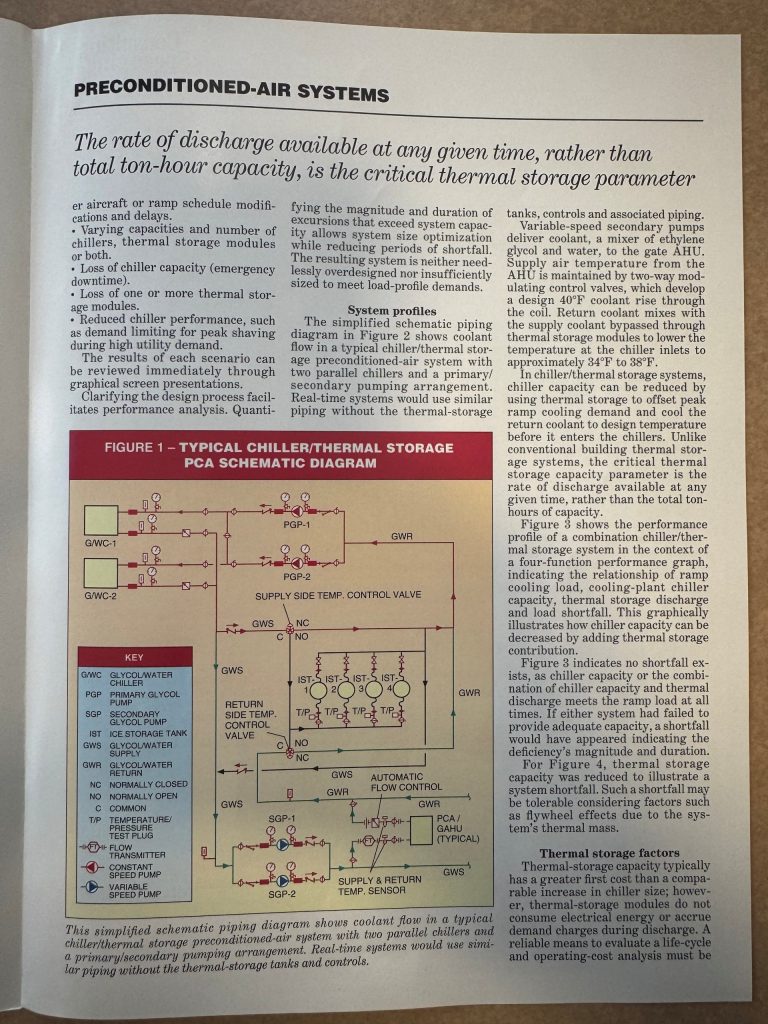

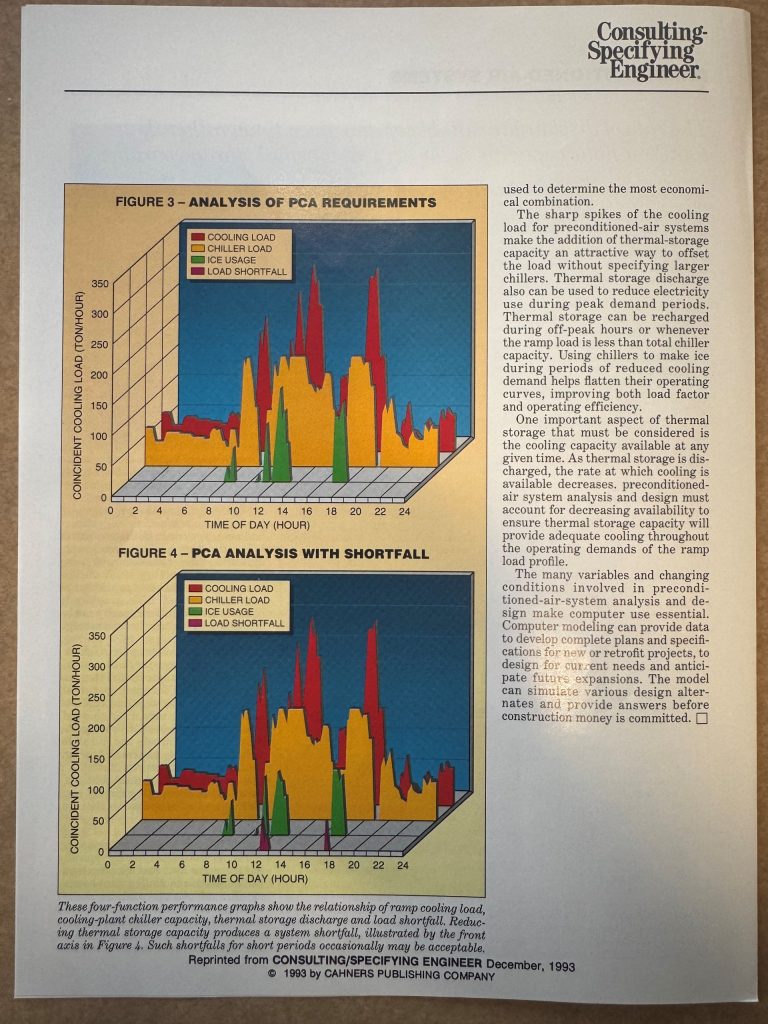

In Orlando, TLC’s long history of work at MCO includes the engineering of PCA-inclusive central utility plants that support Airsides 1, 2, and 3, as well as the South Terminal complex. These efforts collectively represent thousands of tons of central plant capacity and multiple PCA integration studies, each one reinforcing TLC’s deep technical roots in aviation cooling strategies. Likewise, at Tampa International Airport, the team’s PCA system designs extend across Airsides A, C, D, E, and F. Each installation is tailored to the terminal’s operational needs, several incorporating load-responsive capacities and even ice storage integration to optimize energy performance and system resilience.

TLC’s PCA journey continues to evolve, underscoring a legacy of engineering systems that not only stand the test of time but receive ongoing support from the very team that designed them. As airports continue to prioritize energy efficiency and low-emission operations, PCA will remain a critical element of terminal planning, and TLC is uniquely positioned, with decades of institutional knowledge and award-winning designs behind it. Take a look back with us at this recently rediscovered article from the early 1990s.