Seattle-Tacoma International Airport Centralized Pre-Conditioned Air System

Overview

Sea-Tac is committed to being a national leader in sustainable port operations. An environmental steward, Sea-Tac built an energy-efficient centralized plant to supply preconditioned air (PCA) to its 73 gates. The PCA system allows aircrafts to turn off their engines while continuing to heat or cool the plane during boarding or deplaning.

Features

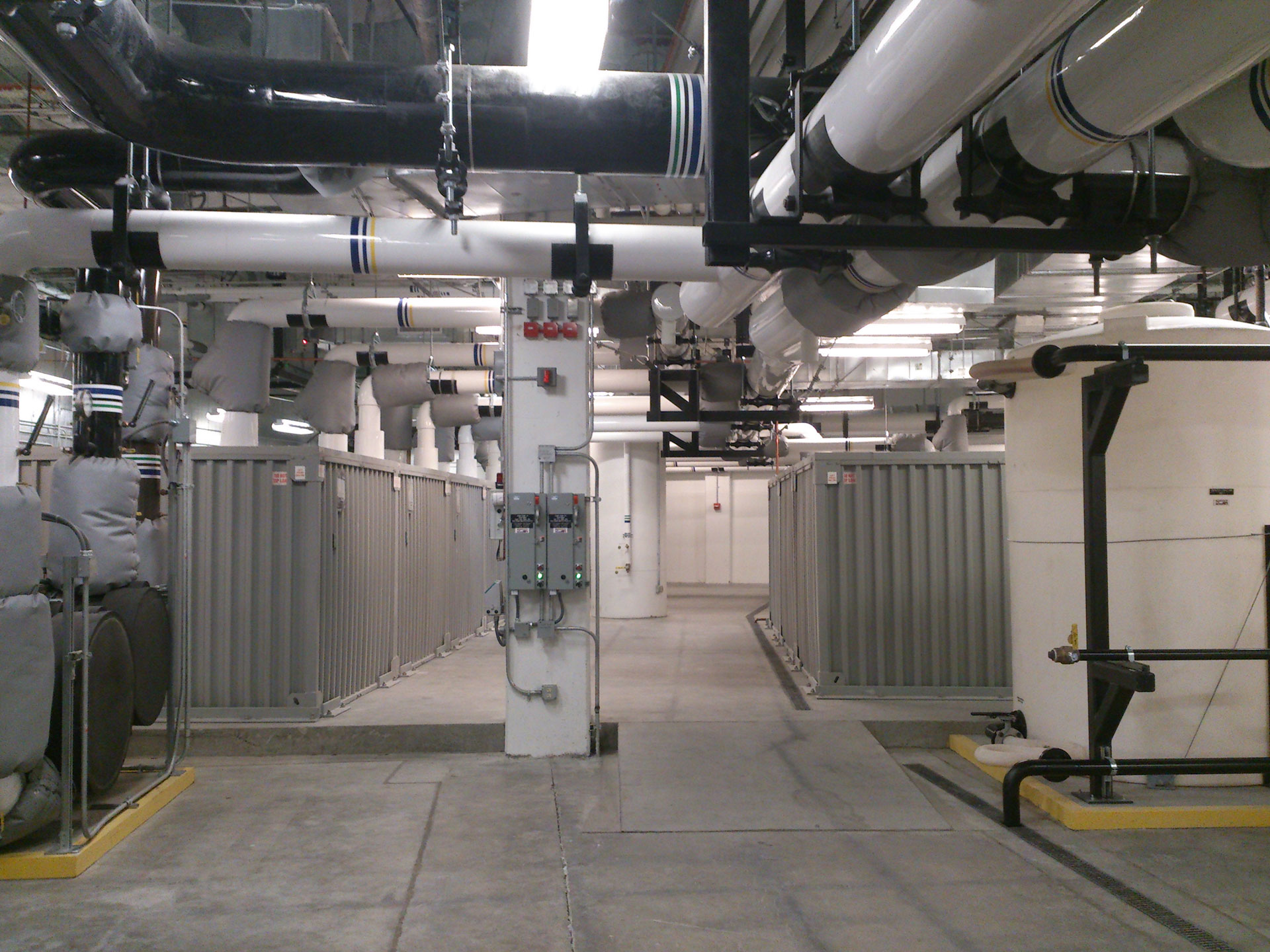

More than 15 miles of piping installed within the existing terminal connects the gates to the new central plant, providing 1,500 tons of cooling capacity with N+1 redundancy on the chillers and pumps. Sea-Tac’s PCA system is projected to save airlines $15 million in fuel costs from the reduction of fuel use. In addition to the savings, noise levels on the apron are significantly reduced since jet engines are no longer running needlessly.