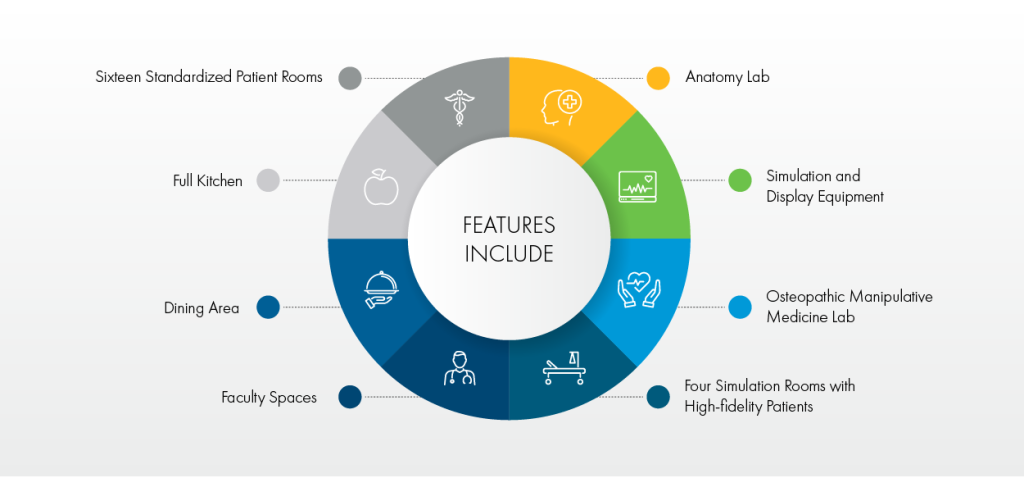

With a history of renovations, repurposing, and the absence of as-built drawings, this $34 Million renovation of a multi-story building came with unique challenges. The facility houses the Baptist University College of Osteopathic Medicine (BUCOM) and marks a notable milestone for the Memphis community as the first School for Doctor of Osteopathic Medicine in West Tennessee. Thoughtful features in the design help provide students with opportunities to simulate patient interactions, preparing them for real-life clinical scenarios.

TLC carefully navigated integrating interior renovations with an older existing two-story structure that had undergone previous renovations for adaptive reuse. The building was originally constructed as a 50,000 sf, elevated, precast parking deck for an auto dealership. The framing consisted of precast prestressed double tees, precast inverted tee beams, and precast concrete columns. Lateral resistance was a combination of interior concrete shear walls, perimeter precast wall panels, and moment frames. Structural drawings for the original construction were not available, but further investigation indicated that the foundations were on piles.

Sometime later, the building was converted again and a roof and walls were added to enclose the second floor, creating athletic courts and office space. This upper-level framing was built using pre-engineered building components, including rigid frames and cable-braced frames. The only available as-built structural documents were for a 1998 renovation of the second story that also included a small addition.

The existing mechanical, electrical, and fire protection systems could not be removed, relocated, or interrupted. Additionally, alternative methods for reinforcing members would be required and bracing had to be relocated in other areas because of accessibility. The design and construction team worked together to consider alternatives to accomplish the modifications necessary within these constraints.

The structural scope of the project included support of new mechanical equipment from the steel roof structure, removal of one bay of precast framing for a new two-story space featuring a curving monumental stair, and infill of the floor in another area. Due to the nature of this renovation and the lack of documentation, a site visit was arranged to inspect the framing, determine member sizes and arrangement, and thoroughly understand the structural conditions.

TLC’s structural team could only rely on the building’s original use as a parking deck, loads tables by precast/prestressed concrete manufacturers, and the Precast Concrete Institute. Determinations needed to be made about the capacity of floor elements along with comparisons to code-mandated live loads for the proposed renovation. Although the facility had been used for offices and assembly occupancy, the floor’s actual capacity could not be verified, and the schedule and current use did not permit load testing. Therefore, the double tees were strengthened using structural steel or carbon fiber reinforcement in key areas where design loads were safely determined to exceed capacity.

The curving monumental stair had no intermediate support. Although the top was being supported by a precast beam that had half of its original load removed, the magnitude of reactions from stair stringers required the addition of a separate steel beam and columns. In addition to the modifications required to support new live loads, significant upgrades for current lateral loads were required, specifically in preparation for seismic events. Seismic requirements for the Memphis area had changed since the last structural modification and may not have been a consideration in the original construction.

Portions of one central concrete shear wall on the first floor had to be removed for the interior renovation, and it was noted during the site survey that cable X-bracing in several areas had been cut and removed. To meet requirements, the team designed new concrete shear walls with micropile foundations at the lower level. They also located replacement bracing in areas of the upper level and improved the connection of the floor diaphragm to the perimeter precast walls.

The mechanical, electrical, and plumbing design provided systems to accommodate the facility’s new functions and work with the existing conditions. For instance, the new HVAC systems were tied into the existing chilled water loop to provide efficient cooling throughout. Heating to the building is provided by a mix of an existing natural gas boiler plant and a new modulating natural gas boiler plant with a variable primary pumping arrangement. A new heating hot water distribution piping system with variable flow pumps was provided to distribute hot water to the various air handling units (AHUs) and Variable Air Volume Terminal units (VAVs). The new boiler system was sized for N+1 redundancy of the boilers and the hot water pumps. Ventilation demand control sequences were implemented to modulate ventilation rates to be proportional to actual occupancy.

The new anatomy lab requires high levels of ventilation air change rates. To provide the highest efficiency and lowest energy cost, a packaged DX system with hot gas re-heat and energy recovery systems was designed in a 100% outdoor air configuration. The individual lab spaces were provided with lab air control valves to allow the building operators to adjust the air change rates based on intended occupancy and schedules and to maintain a slightly negative pressurization at all times. The main anatomy lab space includes the use of mobile dissection tables with integrated exhaust. The HVAC system incorporates exhaust duct taps so that the mobile dissection tables can be used on demand with quick integration into the exhaust system.

Part of the BUCOM mission is to prepare future physicians and scientists who are committed to improving the health of the diverse populations in the Mid-South region of Tennessee, Arkansas, and Mississippi with a special emphasis on primary care in underserved urban and rural areas. This 100,000 sf facility helps advance the BUCOM mission and vision to be distinguished regionally, nationally, and globally for excellence and innovation in osteopathic medical health education with state-of-the-art technology and amenities.