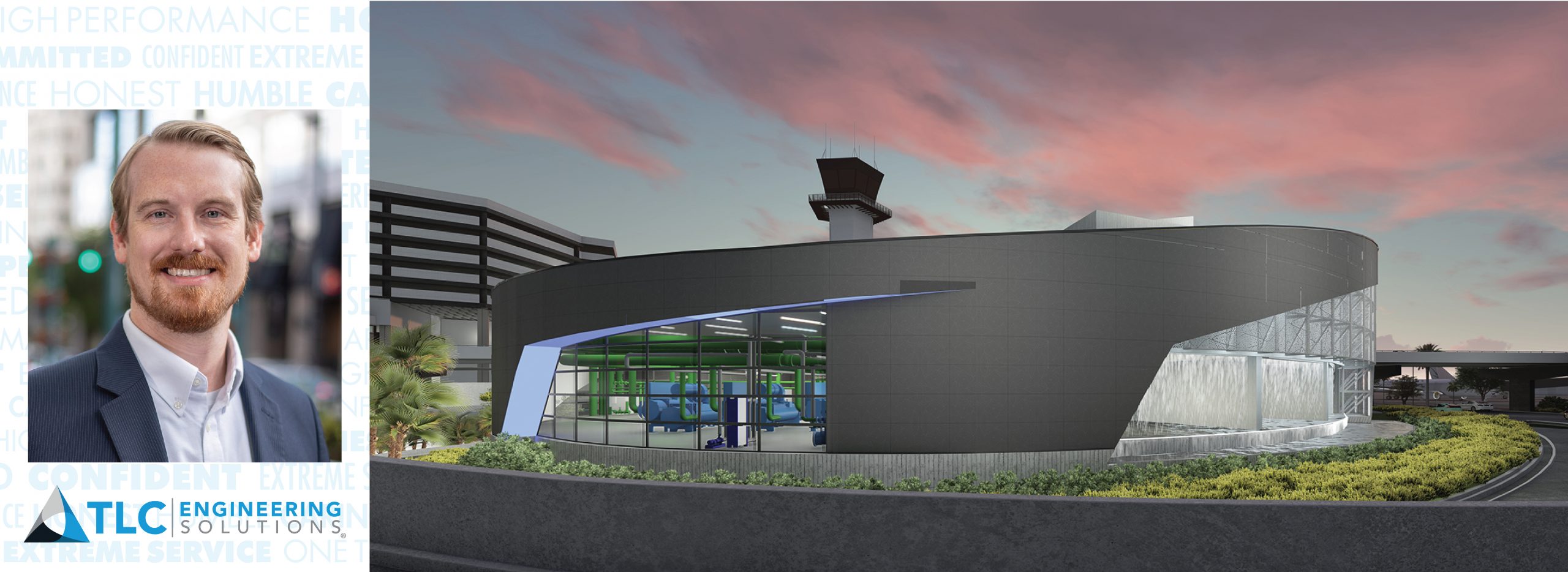

At TLC, we believe our people are our most valuable asset. We continually invest in our employees and provide a variety of ways for them to grow, succeed, and shine. Whether it’s working on projects, helping out in the local community, or simply lending a helping hand to their coworkers, we frequently have employees who go above and beyond. Today’s Behind the Scenes segment will focus on our top energy modeler, Cory Duggin!

TELL US ABOUT YOUR INVOLVEMENT AT TLC AND WHAT YOU DO?

Cory: My primary role is leading the building performance simulation efforts. Whether that be helping folks understand how to accomplish the goals of their projects to training our folks to better understand what our clients are asking for and how to produce that. I really focus on trying to raise up the technical ability specifically as it relates to modeling our designs and the effects that our designs have on the comfort, energy, and productivity of the building and its occupants.

WHAT GOT YOU INTERESTED IN Energy Modeling?

Cory: A long time ago in a galaxy far, far away I was interested in the aerospace industry. There was an air force base near where I grew up and they got to test all sorts of cool stuff like jet engines, nose cones of missiles, re-entry vehicles and all that good stuff. I ended up interning there for four summers and worked for the technology department. Our department would often use simulations to figure out the capabilities of designing new systems or enhancements. So that is what led me towards the simulation aspect.

The base wasn’t hiring due to budget cuts so I decided to continue studying in school. After my wife and I attended Tennessee Tech for undergrad, I decided to return for grad school and it just so happened the only professor who had a teaching assistant position at the time was the HVAC professor. He wanted to start doing some sort of building performance simulation that was HVAC-centric, so that was really how I crossed those paths.

When it came time to get a job, I didn’t really know the state of the HVAC industry but I had experience running simulations in eQuest. At the time that was something that didn’t really fit any of the positions TLC had available but after interviewing with Steve Kemp, folks here saw value in my abilities and created a position to fit me in.

IF YOU HAD TO GIVE AN INTERESTING FACT ABOUT YOURSELF WHAT WOULD THAT BE?

Cory: I make a fair amount of homemade ice cream. At one point I had three ice cream makers but now I’m down to two. I have one that has a wooden tub, and it’s the old fashion version that’s a lot of work but it’s more of a show than anything. It’s always a fun thing to bring out for cookouts. My primary ice cream maker has a built in compressor now.

I also had to get a membership at the YMCA because after our Italy trip, my wife said I came back 85% gelato. But now I’m looking into doing some gelato experimentation with the ice cream maker. I’ll let you know how that turns out.

WHAT ADVICE WOULD YOU GIVE TO YOUR YOUNGER SELF?

Cory: My general advice is to not be afraid to ask questions. When I started I had no HVAC experience so every time I would encounter something I didn’t know, I would always ask somebody like Lawrin Ellis or Kim Shinn “I need you to help me understand what this does so I can figure out how to apply it to what I’m doing.” So I would say don’t be afraid to ask for help or ask questions so that you can learn how to operate better.

IT SOUNDS LIKE YOU DID A GOOD AMOUNT OF LEARNING ON THE JOB. DO YOU HAVE ANY TIPS FOR THAT?

Cory: There has to be a balance between asking for help and figuring something out for yourself. You can’t just depend on someone to give you the answer all the time because you won’t learn how to figure it out on your own. I think finding the balance of figuring something out for yourself and knowing when to ask for help is important. You don’t want to spend a lot of time unnecessarily and you may never figure it out. That’s why I always tell people not be afraid to ask questions. If I can spend 15 minutes to save you two hours then that’s what I want to do. I want you to figure it out and learn on your own but I don’t want you to take as long as I had to when I learned it myself. It all comes down to figuring out how to best utilize your resources.

WHAT IS YOUR FAVORITE THING TO DO IN YOUR FREE TIME?

Cory: Watch a lot of Netflix. My favorite show right now is Lost in Space, but there’s only two seasons unfortunately.

WHAT IS YOUR FAVORITE THING ABOUT WORKING AT TLC?

Cory: My favorite thing is getting to work on lots of different projects. I get the opportunity to work with a lot of operating units which leads to a nice diverse pool of projects. I also enjoy the people throughout TLC and cherish the good relationships I’ve made over the years.

TELL US ABOUT A COOL PROJECT THAT YOU ARE WORKING ON. WHAT WAS YOUR INVOLVEMENT WITH THIS PROJECT?

Cory: I work on a lot of cool projects. One of the coolest ones I’m working on right now is the energy modeling for the Tampa Airport CEP. We have been doing all the modeling for Dominic Cacolici’s designs and some of it is small but with the CEP we got to look at a lot of different options, and it’s really rare to get a project with enough fee and scope to investigate all of the options. We still have to finish up the final model to figure out how much better it can perform compared to code but it’s looking pretty slick so far.

WHAT DID YOU LIKE MOST ABOUT THAT PROJECT? YOU SAID YOU GET TO EXPLORE MORE OPTIONS?

Cory: This project is a little different because even though there’s physically a building (the CEP) the focus for me is more along the lines of how do we come up with the most energy-efficient and cost effective solution for serving the load to the entire airport. This not only encompasses the existing parts but also the new parts that are yet to be built. So rather than create a building model, we were able to take metered data of the existing chiller plant, find out how much chilled and hot water they are using, and use that data to make a load profile for us to do the modeling. We were able to create a lot of different options without having to spend a lot of time.

WHAT IS THIS WIZARD SHOW I KEEP HEARING ABOUT? CAN YOU TELL ME A BIT ABOUT IT?

Cory: The Wizard Show is the most interactive lunch and learn that I’ve ever seen or been a part of. It’s different because you’re not just sitting there trying to remember information that someone puts on slides. You’re actually interacting, making decisions, and learning from those decisions as the presentation goes on. It then challenges you to make new decisions based on what you learned, all within the timespan of this one presentation. So everyone walks away feeling like they participated and that they learned something they can apply to what they are working on.

That’s why it’s so popular with our clients. We don’t just tell them what we did, we show them what we can do, while teaching them how it could better their designs. As Kim Shinn would say, its live theater so anything can happen.

WHAT ARE YOU LOOKING FORWARD TO IN 2020?

Cory: I’m always looking forward to the next cool project or something new. A lot of times I get the opportunity to be the person who gets to do something for the first time. That also means I am the first person who has to figure it out for themselves. So there can be pressure from that but afterwards it always makes a great story because we got to figure out how to do something for the first time. There’s always some interesting new challenge. I don’t know what’s in the plan for 2020 but I definitely need to come back to Orlando and play some WhirlyBall. Does that count?

That’s all we have for now. Stay tuned for additional interviews and let us know what you thought of this one!